ʻO ka mold plastik kahi mea hana i hoʻohālikelike ʻia me nā mīkini hoʻoheheʻe plastik i loko o ka ʻoihana hoʻoili plastik e hāʻawi i nā huahana plastik i kahi hoʻonohonoho piha a me ka nui pololei. E like me nā ʻano hana hoʻoheheʻe ʻokoʻa, hiki ke hoʻokaʻawale ʻia i nā ʻano ʻano like ʻole.

1. Kiekie-hoonui polystyrene molding make

He ʻano ʻeleʻele e hoʻohana ana i ka polystyrene hiki ke hoʻonui ʻia (bead material i haku ʻia me ka polystyrene a me ka foaming agent) nā mea maka e hana ai i nā mea hoʻopaʻa pahu o nā ʻano like ʻole i makemake ʻia.

ʻO ka manaʻo o ka polystyrene hiki ke hoʻonui ʻia i loko o ka mold, me nā ʻano ʻelua o nā ʻano hana lima maʻalahi a me ka hydraulic straight-through foam plastic molds, ka mea i hoʻohana nui ʻia e hana i nā huahana palaki no nā huahana ʻoihana. ʻO nā mea hana no ka hana ʻana i ia mau mold he alumini, ke kila kila, ke keleawe, etc.

2. Hoʻopili ʻia ka poʻi

Me ka hoʻoheheʻe ʻana a me ka hoʻoheheʻe ʻana i ʻelua ʻano mold structural. He ʻano ia o ka mold i hoʻohana nui ʻia no ka hoʻoheheʻe ʻana i nā plastic thermosetting, a ʻo kā lākou mau mea pono he mīkini paʻi paʻi.

E like me nā hiʻohiʻona o ka plastic, ua wela ka mold i ka mahana hoʻoheheʻe (maʻamau 103 ° 108 °), a laila hoʻokomo ʻia ka pauka hoʻoheheʻe ʻia i loko o ka lua a me ke keʻena hānai, ua pani ʻia ka mold, a ua wela ka plastic ma lalo o ka wela nui a me ke kaomi kiʻekiʻe. E hoʻomaʻamaʻa i ka kahe viscous, paʻa a hoʻohālikelike ma hope o kekahi manawa, a lilo i ke ʻano huahana i makemake ʻia.

ʻO ka ʻokoʻa ma waena o ka hoʻoheheʻe ʻana a me ka hoʻoheheʻe ʻana, ʻaʻohe keʻena hānai ʻokoʻa. Hoʻopili ʻia ka ʻōpala ma mua o ka hoʻoheheʻe ʻana, a ua hoʻomaʻamaʻa mua ʻia ka plastic i loko o ke keʻena hānai a lilo i moku kahe viscous. Ma lalo o ka hana o ke kaomi, ua hoʻoponopono ʻia a hoʻopaʻa ʻia i loko o ka lua mold e paʻakikī a hana.

Hoʻokumu nui ʻia ka mold compression i ka lua, ka ʻai ʻana, ke alakaʻi ʻana, nā ʻāpana ejecting, ʻōnaehana hoʻomehana, a me nā mea ʻē aʻe. ʻO nā mea i hoʻohana ʻia i ka hana ʻana i nā mold compression e like me ka injection molds.

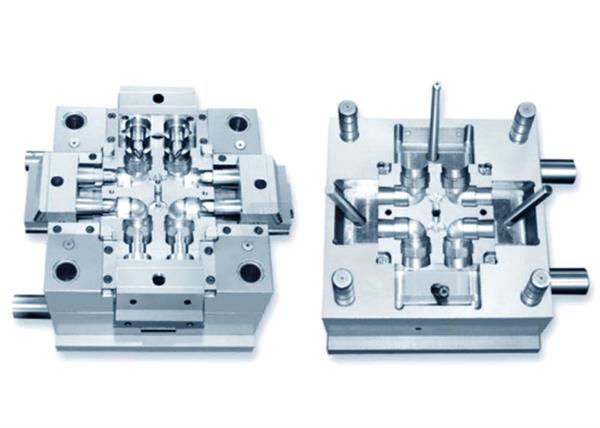

3. Injection mold

ʻO ia ka mea hoʻoheheʻe ʻia i hoʻohana pinepine ʻia i ka hana ʻana i nā ʻāpana thermoplastic. ʻO nā mea hana hana e pili ana i ka mīkini hoʻoheheʻe he mīkini hoʻoheheʻe injection. Hoʻomaʻamaʻa mua ʻia ka plastik a hoʻoheheʻe ʻia i loko o ka pahu hoʻomehana ma lalo o ka mīkini hoʻoheheʻe injection. Ma lalo o ke kaomi ʻana o ka plug, komo ia i loko o ka mold cavity ma o ka injection molding machine nozzle a me ka ʻōnaehana hoʻoheheʻe ʻana o ka mold, a hoʻomaʻalili ʻia ka plastic a paʻakikī e hana, a loaʻa ka huahana ma ka demolding.

Hoʻokumu pinepine ʻia kona ʻano me ka hoʻokumu ʻana i nā ʻāpana, ka ʻōnaehana ninini, nā ʻāpana alakaʻi, ka mīkini paʻi-waho, ka ʻōnaehana hoʻoponopono wela, ka ʻōnaehana exhaust, nā ʻāpana kākoʻo a me nā ʻāpana ʻē aʻe, a ua hana ʻia ia me ke kila kila. ʻO ke kaʻina hana hoʻoheheʻe ʻia e kūpono wale no ka hana ʻana i nā huahana thermoplastic. ʻO nā huahana plastik i hana ʻia e ke kaʻina hana hoʻoheheʻe injection he ākea loa. Mai nā mea e pono ai i kēlā me kēia lā a hiki i nā mea uila paʻakikī a me nā ʻāpana kaʻa, ua hana ʻia lākou me nā mold injection. ʻO kekahi o nā kaʻina hana i hoʻohana nui ʻia i ka hana ʻana i nā huahana plastic.

4. Puhi po'i

Hoʻohana ʻia e hana i nā huahana hollow ipu plastik (e like me nā ʻōmole inu, nā huahana kemika i kēlā me kēia lā a me nā pahu pahu ʻē aʻe). ʻO ke ʻano o ka hoʻoheheʻe ʻana e pili ana i ka extrusion blow molding a me ka injection molding e like me ke kaʻina hana. ʻO ke kumu nui e pili ana i ka extrusion blow molding, injection blow molding, injection extension blow molding (i ʻike pinepine ʻia ʻo ka injection stretch blow), multi-layer blow molding, sheet blow molding, etc. ʻO ka mīkini hoʻoheheʻe ʻana, a ʻo ka hoʻoheheʻe ʻana he mea kūpono wale nō no ka hana ʻana i nā huahana thermoplastic. He mea maʻalahi ke ʻano o ka ʻōpala puhi, a ʻo nā mea i hoʻohana ʻia i hana ʻia me ke kalapona.

5. Make extrusion

ʻO ke ʻano o ka mold i hoʻohana ʻia no ka hana ʻana i nā huahana plastik hoʻomau, ʻike ʻia hoʻi ʻo extrusion molding head, i hoʻohana nui ʻia i ka hana ʻana i nā paipu, nā kaola, nā monofilaments, nā papa, nā kiʻiʻoniʻoni, nā uea a me nā ʻāpana kelepona, nā mea profiled, etc.

ʻO nā mea hana hana kūpono he extruder plastic. ʻO ke kumu o ka hoʻoheheʻe ʻia o ka plastic paʻa a hoʻoheheʻe ʻia ma lalo o nā kūlana o ka hoʻomehana a me ka hoʻololi ʻana o ka wili o ka extruder, a hana ʻia i loko o ka ʻāpana like ʻole e like me ke ʻano o ka make ma o ka make o kahi ʻano kikoʻī. Nā huahana plastik mau. ʻO kāna mau mea hana ka nui o ke kila carbon structural, nā mea hana hao, a me nā mea ʻē aʻe, a ua hoʻokomo pū ʻia kekahi mau make extrusion me nā mea paʻa e like me ke daimana ma nā ʻāpana e pono ai ke ʻaʻahu.

ʻO ke kaʻina hana extrusion he kūpono wale nō ia no ka hana ʻana i nā huahana thermoplastic, ʻokoʻa loa ia mai nā mold injection a me nā mold compression i ke ʻano.

6. Puka pohū

ʻO kahi poni e hoʻohana ana i nā pā palaka a me nā ʻili e like me nā mea maka e hana ai i nā huahana plastik maʻalahi. I ka hihia o ka palupalu, ua deformed a hoʻopili ʻia i ka lua o ka mold e loaʻa ai ka huahana i makemake ʻia, i hoʻohana nui ʻia i ka hana ʻana i kekahi mau mea e pono ai i kēlā me kēia lā, nā meaʻai a me nā huahana pāʻani pāʻani.

Ka manawa hoʻouna: Feb-12-2022